Introduction

Welcome to the Komaspec complete guide to contract manufacturing (CM). We’ve put this guide together to help you understand how contract manufacturing works, when you should use a contract manufacturer, and how to choose the right one.

Contract manufacturing offers great potential. Companies that delegate production to a third-party manufacturer can:

- Benefit financially

- Gain access to their manufacturer’s expertise, resources, and supply network

- Enjoy far more business flexibility

They can also focus on other important parts of their business, like product innovation, marketing, and customer relationships, while their contract manufacturer handles production. It is, however, a big step to take, and one that requires knowledge of the CM process and careful planning. This guide will equip you with the tools to take that step.

Part 1: An Overview of Contract Manufacturing

In Part 1 of this guide, we will explain exactly what contract manufacturing is, the different forms contract manufacturing takes, and provide an overview of the different types of contract manufacturers.

Part 1 Table of Contents:

- Introduction

- Part 1 Key Takeaways

- What Is Contract Manufacturing?

- What Forms of Contract Manufacturing Are There?

- What Types of Contract Manufacturer Are There?

- The Advantages and Disadvantages of Contract Manufacturing

- Which Industries Use Contract Manufacturing?

- When Should You Use Contract Manufacturing?

Part 1 Key Takeaways

- Contract manufacturing can cut costs, provide production expertise and resources, and free up time for the company.

- Contract manufacturers work in every production discipline and produce everything from individual components to entire products.

- Companies should understand how ODMs, OEMs, and other types of models work before looking at manufacturers.

What Is Contract Manufacturing?

Definition

Contract manufacturing is a business practice in which a company outsources the production of its products (or parts or components of its products) to a third-party manufacturer.

The hiring company will specify product requirements for the contract manufacturer to follow. This will usually include a design or an example of the part, component, or product that will be manufactured. The contract manufacturer will then offer a quote for everything involved in producing that part, component, or product. Once a formal contract manufacturing agreement is reached, a contractual deal is signed between the parties.

In some variations of contract manufacturing, the contract manufacturer also handles processes other than production, such as assembly or packaging.

Examples of Contract Manufacturing

The most well-known example of contract manufacturing is Apple’s use of the Taiwan based electronics manufacturer Foxconn. Foxconn produces approximately two-thirds of the iPhones that Apple sells. They are skilled and reliable suppliers, allowing Apple to focus on innovation and marketing rather than worrying about production.

Pharmaceuticals is another product category often outsourced to specialist manufacturers. Pfizer, for example, has long outsourced much of its production. And in 2020, the company shifted even more of its production to a network of contract manufacturers, allowing it to focus its in-house resources on producing COVID-19 vaccines.

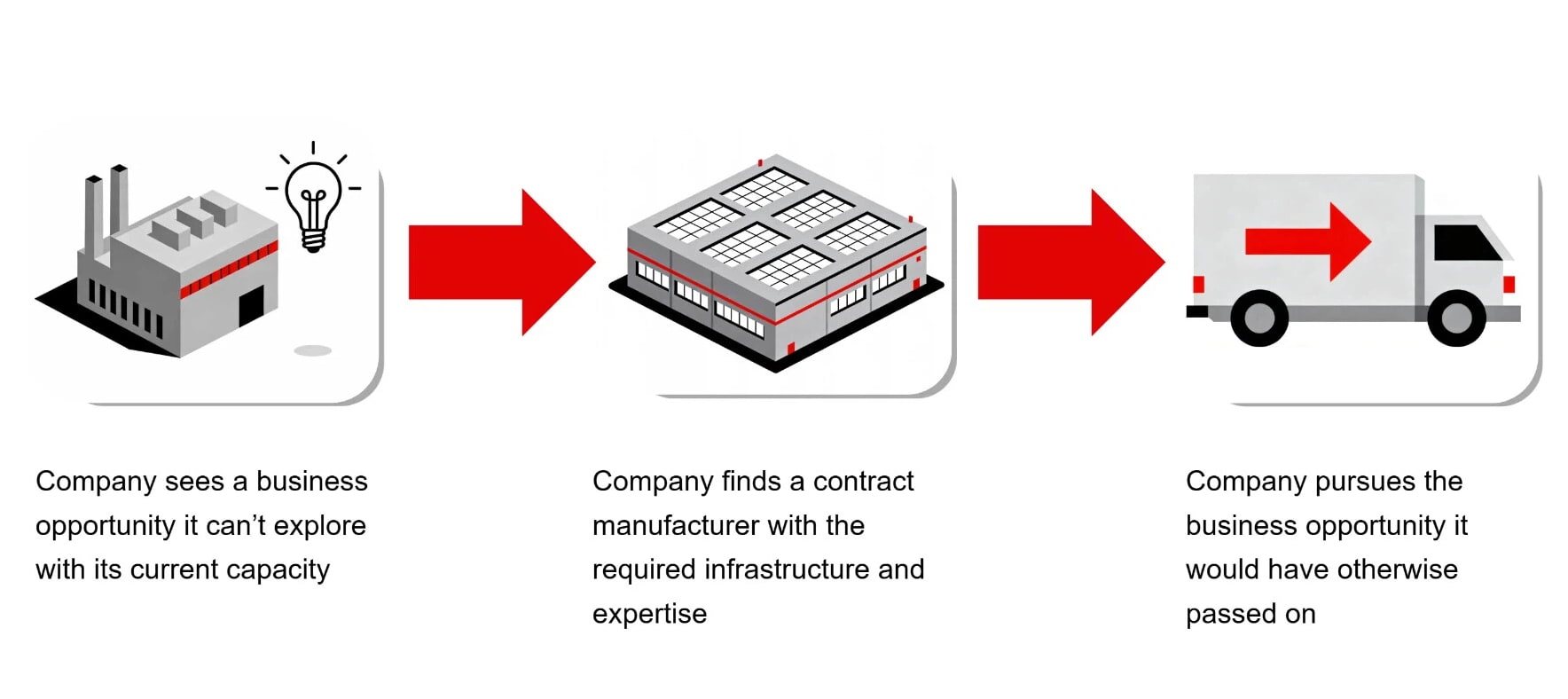

Suppose a company with an existing product line sees an opportunity to sell a new product that is outside of the category it normally produces. Building manufacturing facilities to seize that opportunity would be costly, slow, and highly inefficient. Instead, they could choose to hire a contract manufacturer to make the product for them at a fraction of the investment and with a faster speed to market.

The process would involve:

1. Finding a contract manufacturer with the right skills, resources, and capacity to handle production.

2. Supplying the manufacturer with designs or a prototype. In some cases, they may consult with the manufacturer on design.

3. Establishing a formal contract manufacturing agreement.

This arrangement allows the company to:

- Explore its new product idea without investing in new production facilities

- Tap the manufacturer’s resources and expertise

- Begin production quickly

- Have the flexibility to increase or decrease production levels as needed

Other Hypothetical Situations

Other scenarios in which you might use a contract manufacturer include:

- Your company is completely new

- Your company experiences a surge in demand for an existing product

- You see an opportunity to sell a white label product

What Is a White Label Product?

White label products are products that a contract manufacturer designs and produces for a hiring company to sell as if they are its own products. Often, these are generic products like phone cases or t-shirts that are given a company’s branding. However, some white label products are more imaginative, like shower curtains or food items.

What Forms of Contract Manufacturing Are There?

Contract manufacturing is a broad category, which can include different tasks and arrangements. Here are the major forms it can take.

Part and Component Manufacturing

Some hiring companies will outsource the production of parts or components, rather than the entire product. This is often the case when unusual or specialized parts are needed, or where part requirements are variable. The automobile industry, for example, tends to rely on specialist manufacturers, like Bosch, which makes components for many car manufacturers.

Sub-Assembly Manufacturing

In sub-assembly contract manufacturing, a third party is used to manufacture a sub-assembly that is then incorporated with other units in a finished product. This is similar to part and component manufacturing, except that sub-assemblies are more complex and consist of a number of parts.

This form of contract manufacturing is often used for complicated or unusual sub-assemblies. Manufacturers with specialized skills and equipment can produce these sub-assemblies far more cheaply and easily than non-specialist companies.

The aerospace industry often uses sub-assembly manufacturing. The landing gear of airplanes, for example, might be outsourced to a manufacturer that specializes in this type of work.

Product Manufacturing

Product contract manufacturing is when a third-party manufacturer makes the entire product, rather than components of it. In these arrangements, the hiring company is not directly involved in manufacturing the product it will sell under its own name. It simply requests complete products from their manufacturer and then adds its own branding to it.

The contractor might deliver the finished product directly to the hiring company. In other cases, the product might be sent to distributors or retailers. In a drop-shipping arrangement, the manufacturer will ship the finished product directly to customers.

Product manufacturing is the most comprehensive form of contract manufacturing. It allows the hiring company to focus completely on other areas of business.

Turnkey Manufacturing

The term “turnkey manufacturing”refers to a scenario in which the hiring company is able to delegate every single task related to production to a contract manufacturer.

Other Forms of Contract Manufacturing

- Contract Assembly :

Contract assembly is when a contract manufacturer assembles a product but isn't involved in its fabrication.

Contract assemblers often specialize in assembly work or have skills relevant to a particular product. Electric guitars, for example, have specialist components made by various companies, but one company may be tasked with assembling all of those components to create the finished product.

- Contract Packaging

Contract packaging is when a contractor (sometimes referred to as a “co-packer”) is used to package completed products so it’s ready for distribution.

Co-packers are sometimes used when packaging requirements are complicated. The food and drinks industry, for example, has strict and complicated packaging requirements, so companies often rely on specialist packaging companies to get it right.

- Equipment, Expert Staff, or Facility Hire

In an equipment, expertise, or facility hiring arrangement, the hiring company will arrange to use the contractor’s equipment, expert staff, or production facility for a production run that it manages itself.

What Form Will Suit Your Company?

The best form will depend on your requirements. If you’re in the early stages of looking into contract manufacturing, you simply need to consider what production your company needs to have completed and what form of manufacturing will be most suitable for it.

This is usually straightforward, although it may be worth considering whether your needs are likely to change over time. It might also be worth thinking about how you plan to manage things if you need to pursue more than one form of manufacturing.

Komaspec are specialist electro-mechanical, sheet metal, and plastics manufacturers based in China. We do contract production and contract assembly work for clients all over the world.

What Types of Contract Manufacturers Are There?

Contract manufacturers often perform several roles, and there can be a lot of overlap and flexibility in the exact role a contractor fills.

Contract Manufacturer (CM)

Contract manufacturers that are simply referred to as “contract manufacturers” tend to be generalist contractors that can handle many types of production. While they may lack specialized equipment and expertise, they may provide a higher level of flexibility.

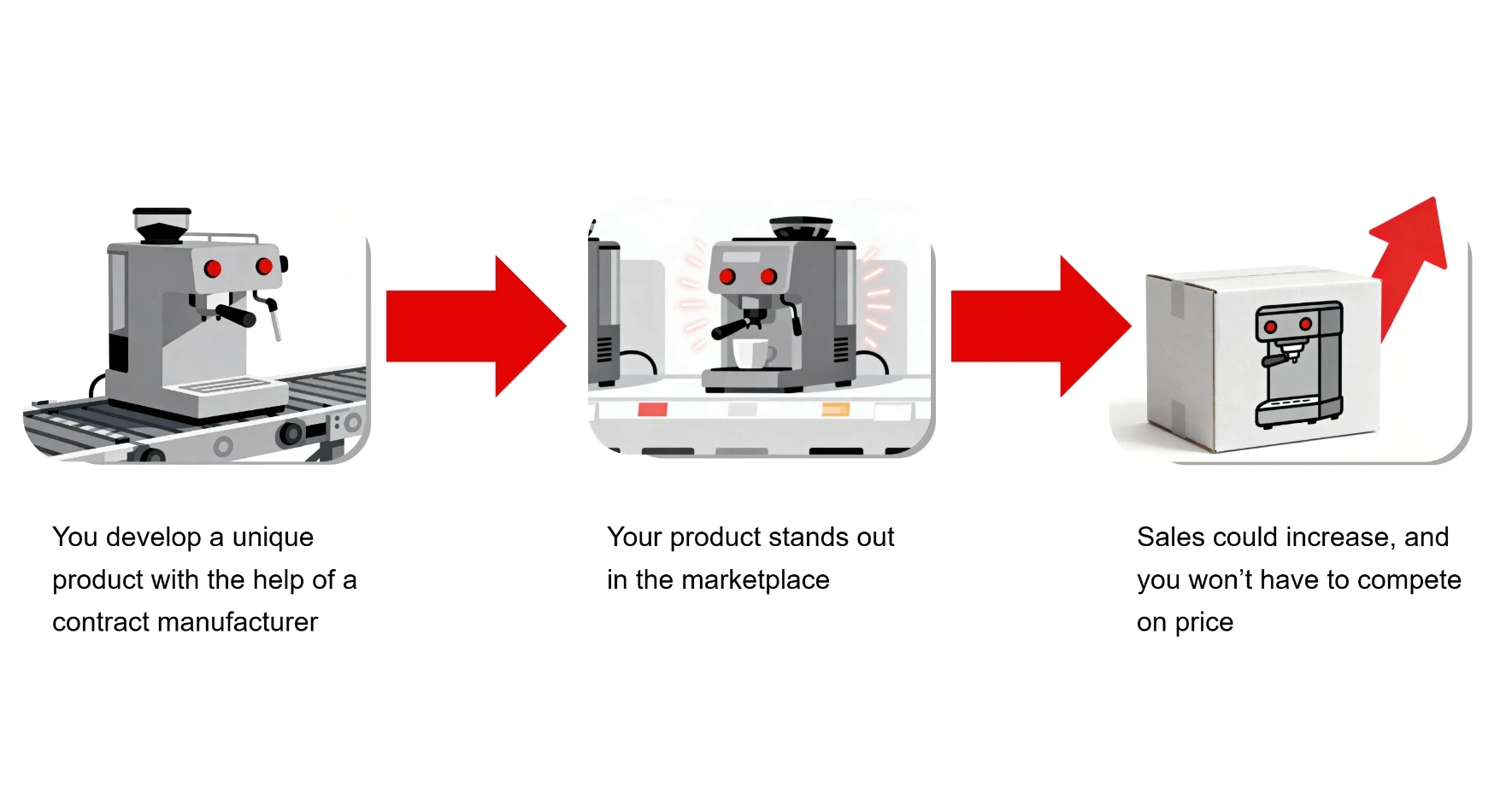

A hiring company could approach a contract manufacturer with designs for a completely unique product, for example. The contract manufacturer would then arrange a new production system from scratch.

Your Company Could Get Ahead with a Unique Product

Find out more about how Shopify sellers stand out in their marketplaces with unique products on our blog.

Original Equipment Manufacturer (OEM)

An OEM manufacturer is a manufacturer that specializes in a product type or category. The hiring company will still supply the manufacturer with specifications for the product they need, but the manufacturer will already have the experience and resources to make products of that type.

In other words, OEM manufacturers have the equipment but not the designs.

Original Design Manufacturer (ODM)

An ODM manufacturer is one that owns designs for the products it manufactures. That means the hiring company doesn’t have to supply designs or prototypes. The ODM simply manufactures a pre-existing product, and the hiring company sells it under its own name. However, some customizations may take place prior to production to create differentiation.

This form of production is also known as white label or private label production.

Other Types of Contract Manufacturer

- Electronics Manufacturing Service (EMS)

The production of electronics is highly specialized work, where things like microchips or circuit boards are included in a product. As such, this part of production is usually outsourced to a specialist.

EMS manufacturers are experts in this product category, and they can produce high-quality specialist parts at speed and at minimal cost.

- Other Specialist Contract Manufacturers

There are other specialist types of contract manufacturer as well. For instance, companies may specialize in making gear mechanisms, which can be too complicated for a generalist contract manufacturer to produce.

How to Compare the Different Types of Contract Manufacturer

Your choice of contract manufacturer will depend largely on your company’s requirements. First and foremost, you’ll want to find a contractor that fits the role. Decision-making can become slightly nuanced, however, so it’s worth considering the relationship structure as well.

The following table shows you some of the main considerations you should make for the three main types of contract manufacturer.

| Original Design Manufacturer (ODM) | Original Equipment Manufacturer (OEM) | Contract Manufacturer (CM) | |

|---|---|---|---|

| Product Design, Development, and Testing Input | No input required for design, development, and testing | Hiring company takes primary responsibility | Both the hiring company and the manufacturer share input |

| Initial Investment | No initial investment needed | Modest investment due to existing tooling and manufacturer preparedness | Highest level of investment - product and manufacturing process are designed from scratch |

| Product Development Time | Minimal (some customization time may be needed) | Moderate (some time needed to finalize the design and prepare for manufacturing) | Highest (time needed to develop the product and arrange the manufacturing process) |

| Design and Tooling Rights | Contractor retains rights to the product | Rights ownership varies, depending on the contract | Usually, the rights belong entirely to the hiring company |

| Supply Chain and Material Transparency | Usually limited (depending on the contractor) | Some visibility into the supply chain and control over materials | More visibility into the supply chain and control over materials |

Thinking long-term when selecting a manufacturer is also advisable. Hiring a company that you can use to manufacture a range of products over time can save you trouble in the long run.

Up Next…

Contract manufacturing offers great benefits for many businesses. In Part 2 of this guide, you’ll learn what kind of businesses use it and when contract manufacturing is most successful.

Part 2: When to Use a Contract Manufacturer

In Part 2 of this guide, we’ll look at when it makes sense to employ a contract manufacturer, including:

- The main advantages and disadvantages of contract manufacturing

- Industries that commonly use contract manufacturing

- How to make the final decision about whether you should look for a contract manufacturer

Part 2 Table of Contents:

Part 2 Key Takeaways

- Many of the disadvantages of contract manufacturing can be overcome by choosing a good manufacturer

- Companies in virtually any industry can use contract manufacturing in some capacity

- Your company’s product objectives and overall business objectives will determine whether it makes sense to hire a contract manufacturer

The Advantages and Disadvantages of Contract Manufacturing

Contract manufacturing will appeal to lots of businesses. It offers huge financial advantages, the chance to gain new production resources, and a much more convenient way to do business. It’s also commonplace nowadays, with many businesses already using contract manufacturers.

Before deciding whether it’s the right approach for you, let’s take an in-depth look at the advantages and disadvantages it offers.

The Main Advantages

Contract manufacturing is faster, more economical, and more effective. It also means a business doesn’t have to worry about managing production.

1.Hidden Costs

While manufacturing costs may be cheaper with a contract manufacturer, there may be some hidden costs. This may include import or export duties, costs associated with regulatory compliance, or higher than anticipated shipping fees.

Unreliable manufacturers will also obscure their pricing. They may add additional fees on top of the main manufacturing fees, for example. They may also charge for repeated prototype production.

2. Loss of Control

This one is generally only a problem if you hand over production to an unreliable contractor. In that case, you may find that product quality standards are low or variable. There may also be deviations from the original design, such as alterations to color. Raw materials or fittings may also be different than the ones you expected or agreed to.

If quality control is a high priority (e.g. if you’re making regulated products), make sure quality control procedures are very robust before production starts.

3. Lower Production Costs

In addition to lower upfront investments, contract manufacturing also offers lower production costs.

Most contract manufacturers are based in China or other Asian countries where labor costs are significantly lower. Overhead costs, such as power or machine maintenance, are also lower in these locations. Contract manufacturers can also run production more efficiently by working for multiple clients.

Specialist manufacturers will likely have refined their operations for cost efficiency. Their staff also provides an economical way to access expertise. Suppliers that work in a particular category can also benefit from economies of scale when purchasing raw materials.

Check out this article to learn more about how contract manufacturing could reduce your costs.

4. Gain Access to Supplier’s Skills and Resources

Many contract manufacturers are leaders in their field of production. Their labor force is filled with experts, specialists, and skilled workers. Working with them makes this experience and expertise available without you needing to hire a full staff of engineers, machinists, and other technical personnel. Contractors may also have advanced equipment that your company may not otherwise be able to afford.

Furthermore, contract manufacturers may have very good quality control procedures in place from their years of experience.

Taken together, this can result in greater quality, faster and cheaper production, and a reduction in defects and rework.

5. Enhanced Production Flexibility and Scalability

Contract manufacturing makes it far easier to adjust production volumes as demand rises or falls.

There are certain constraints that apply, however. For instance, larger production volumes may get a discounted rate. Conversely, a manufacturer may need to charge extra to accommodate a sudden increase in demand. Even with these constraints, production volumes are much more adaptable than they would be if you were doing it all in-house.

6. Focus on Core Competencies

Outsourcing manufacturing means you don’t have to worry about day-to-day production issues. This means your company can focus on other areas of business, like product research, marketing campaigns, or providing better customer service. These could all become differentiators that give you a real competitive edge.

The Main Disadvantages

While the benefits of working with a contract manufacturer can be significant, there are some disadvantages that should be taken into account.

1. Hidden Costs

While manufacturing costs may be cheaper with a contract manufacturer, there may be some hidden costs. This may include import or export duties, costs associated with regulatory compliance, or higher than anticipated shipping fees.

Unreliable manufacturers will also obscure their pricing. They may add additional fees on top of the main manufacturing fees, for example. They may also charge for repeated prototype production.

2. Loss of Control

This one is generally only a problem if you hand over production to an unreliable contractor. In that case, you may find that product quality standards are low or variable. There may also be deviations from the original design, such as alterations to color. Raw materials or fittings may also be different than the ones you expected or agreed to.

If quality control is a high priority (e.g. if you’re making regulated products), make sure quality control procedures are very robust before production starts.

3. Cultural and Communication Challenges

Hiring companies sometimes underestimate the depth of the relationship they will enter into with their supplier. As a result, they may downplay the difficulties they’ll face from communication challenges and cultural differences. In reality, these can become significant obstacles, so it’s important to account for them from the outset.

It’s often a good idea to stop and take some time to understand the cultural and business practices in the country you will outsource to early on. Be aware that working with an oversees contractor makes it expensive and time-consuming for you to pay their factory a visit.

4. Capacity Constraints

Another common pitfall is that a contract manufacturer may not always be able to increase output if your demand increases. The manufacturer’s output capacity may also fluctuate over time as it deals with other clients.

Try and predict long-term capacity requirements at the outset to ensure that the contractor can handle them. Early communication can also help you figure out whether changing volume requirements will be an issue.

5. Overdependence

Overdependence can develop over the course of a long-term supplier-client relationship. If production is disrupted for any reason at a critical supplier, this can cause serious problems for your ability to get products to distributors and customers.

6. Product Copying

Intellectual property issues can also arise if protections aren’t in place. If design and production information isn’t kept securely, it may be stolen and used to create counterfeit copies of your products. This can happen even if an NDA has been signed, with untrustworthy employees stealing files.

Contract Manufacturing: Pros & Cons

Which Industries Use Contract Manufacturing?

Contract manufacturing is not restricted to particular industries. It’s a practice used across all industries. Even in industries where the practice is less common, companies still frequently use contract manufacturers to produce parts and components.

That said, here are a few industries in which contract manufacturing is especially common.

Electronics

In electronics, a huge amount of manufacturing is outsourced to contract manufacturers. Much of the manufacturing work in this industry is highly specialized, and contract manufacturers can perform this specialist work at fast speeds and reduced cost. This allows brands to focus on innovation and marketing while production happens in an optimal way.

In the electronics industry, contract manufacturers routinely handle the production of parts, components, or entire products.

Automotive

Vehicle assembly and the production of automotive components and sub-assemblies are often outsourced to contract manufacturers. Gear systems, wiring systems, and electrical components are normally outsourced. Assembly is often carried out by dedicated contractors that specialize in this process.

Consumer Goods

Consumer goods are often outsourced to contract manufacturers, particularly by startups and SMEs. These companies will commonly rely on contract manufacturers to make whole products, rather than parts or components. Manufacturers in countries like China can make consumer products cheaply, quickly, and at high quality, making it an obvious choice for many companies.

Komaspec are experienced in new product introduction for the consumer goods industry. This includes for crowdfunded Indiegogo and Kickstarter companies, as well as for companies that sell through Shopify.

Pharmaceuticals, and Health and Beauty

Drugs are frequently manufactured by specialist contractors, often as part of long-term relationships with big companies like Pfizer. However, shorter-term arrangements are often used for products like supplements.

In the health and beauty industry, chemical-based products like cosmetics and shampoo are typically outsourced.

In addition to manufacturing, these industries often rely on co-packers to package their products.

Other Industries

Contract manufacturing is also common in the aerospace, defense, semiconductor, chemical, medical, energy, and food manufacturing industries. However, any business, regardless of industry, can make use of contract manufacturing if it fits their production goals.

When Should You Use Contract Manufacturing?

The amount of thought that goes into this decision will vary significantly between companies.

For startups selling white label products, the decision is simple. Contract manufacturing is obviously the way to go. Businesses with more complex production requirements and more uncertain future goals will need to think through the decision more carefully.

The Decision-Making Process

1. A good starting point is to define your company’s short-term objectives with the product.

2. Next, consider your long-term objectives with the product and as a business overall. Consider business and product targets and deadlines.

3. Then, consider your business objectives against what contract manufacturing will offer to your business. Review the advantages and disadvantages of contract manufacturing to see if they align with your needs.

4. Think about future factors that may come into play with each decision. In-house manufacturing will bring uncertainty about management input, for example, while outsourcing comes with uncertainty about contractor reliability.

The amount of thought that goes into this decision will vary significantly between companies.

For startups selling white label products, the decision is simple. Contract manufacturing is obviously the way to go. Businesses with more complex production requirements and more uncertain future goals will need to think through the decision more carefully.

The Decision-Making Process

1. A good starting point is to define your company’s short-term objectives with the product.

2. Next, consider your long-term objectives with the product and as a business overall. Consider business and product targets and deadlines.

3. Then, consider your business objectives against what contract manufacturing will offer to your business. Review the advantages and disadvantages of contract manufacturing to see if they align with your needs.

4. Think about future factors that may come into play with each decision. In-house manufacturing will bring uncertainty about management input, for example, while outsourcing comes with uncertainty about contractor reliability.

Up Next…

Your success with contract manufacturing also depends on what contractors are available and how you handle the business relationship. In Part 3, we’ll show you how to find prospective contract manufacturers, evaluate their capabilities, and maintain a good working relationship in the long run.