How to Make a Product in Vietnam

- Introduction

- Key Takeaways

- Why Choose Vietnam for Manufacturing?

- What Kind of Products Can Be Made in Vietnam?

- How to Manufacture a Product in Vietnam: A Step-by-Step Guide

- An Emerging Manufacturing Powerhouse

- FAQs

Introduction

Vietnam is one of the most talked about China “alternatives” but with even with the sheer number of multinationals and SMEs looking to shift a portion or all of their manufacturing to the country, there’s a lack of understanding about Vietnam’s supply chain, its strengths and weaknesses, and the industrial clusters that are already in place. We’re exploring the basics of what it takes to develop or source a new product and manufacturing in Vietnam.

It can be challenging to finding the right factory in Vietnam, but probably the bigger challenge is that the ease of manufacturing in China (tons of white label manufacturers on Alibaba and Global Sources, huge online factory directories, well attended industrial fairs, etc.) has spoiled a lot of companies and lowered the barrier to international contract manufacturing. So we’ll take a step by step approach and bring you through the process from conception to product launch.

Key Takeaways

- Low labor costs and specialties in major industries make Vietnam a competitive manufacturing hub.

- Well-planned RFQs help mitigate unexpected costs and allow for accurate business quotes.

- Clear manufacturing specifications are crucial for selecting the right manufacturer.

- Manufacturers should be properly vetted and tested before running a full production order.

Table of Contents

Why Choose Vietnam for Manufacturing?

There are four major advantages to making a product in Vietnam.

1. Diversified Supply Chain

This is generally the number one reason customers approach us about manufacturing in Vietnam. The geopolitical landscape seems to becoming more and more complex, and the last ten years have seen huge shifts in global manufacturing. For a lot of companies who still need access to China’s advanced component and electronics supply chain, but who want to reduce risk of tariffs or trade tensions, Vietnam is a logical choice for customers looking for a “China plus one” option (meaning having production in China and another location rather than concentrated purely in China. Vietnam has its own burgeoning domestic supply chain and is increasing its capabilities to produce any number of components, so there is less reliance on Chinese components, but still easy access if needed.

2. Affordable Labor Costs

The most obvious advantage is the labor expense, which are approximately 40 to 60% of what they are in China. This is most important for products with a high value content: think clothes, textiles, and any product that still requires a lot of manual labor to produce (highly customized, not easily automated, small batches, etc.). It’s much less relevant for highly automated or standardized products (e.g. LEDs, PCBAs, mass consumer products).

3. Free Trade Agreements

Vietnam has entered into a number of strategic Free Trade Agreements (FTAs).

These include:

- Comprehensive and Progressive Agreement for Pacific Trade (CPTPP), allowing duty-free access with Canada, Mexico, and Japan

- EU-Vietnam Free Trade Agreement (EVFTA), eliminating 99% of EU tariffs on electronics, shoes, and other non-foodstuffs by 2027

- Regional Comprehensive Economic Partnership (RCEP), ensuring free trade between 15 Asia-Pacific countries to make sourcing components easier

Together, these agreements make it easier to source materials and more affordable to import and export goods from the country.

4. Attractive Investment Incentives

The Vietnamese government has actively courted international corporations through Foreign Direct Investment (FDI) programs. This strategy has paid off, attracting 3,375 new projects in 2024, with a total of nearly $20 million USD in newly invested capital.

These investments have led to a growth in Vietnam’s manufacturing ecosystem, which has grown by 10.3% in the first seven months of 2025 alone.

What Kind of Products Can Be Made in Vietnam?

Vietnam has a diverse manufacturing ecosystem that can handle various types of production.

However, the country is strongest in a few major categories, including:

- Apparel and Textiles

- Footwear

- Furniture and Wood Products

- Consumer Electronics

- Injection Molding and Plastics

- Automotive components

The Vietnamese government is also targeting investments to strengthen the country’s semiconductor production to support the influx of large-scale electronics manufacturers (BYD, Foxconn, LG, Samsung, etc.). This three-phase strategy aims to grow semiconductor manufacturing in Vietnam into a $100 billion/year industry by 2050 through manufacturing plants, research facilities, and an increased in skilled engineering talent.

There are, however, some limits to what can be produced in the country. This is especially true for things like advanced semiconductors and precision optical equipment, which are notoriously difficult to manufacture well. Vietnam also has a much smaller native upstream supply chain for components, everything from motors to pumps to machined parts to tools. That being said, the manufacturing sector continues to grow and these capabilities may begin to emerge in the near future.

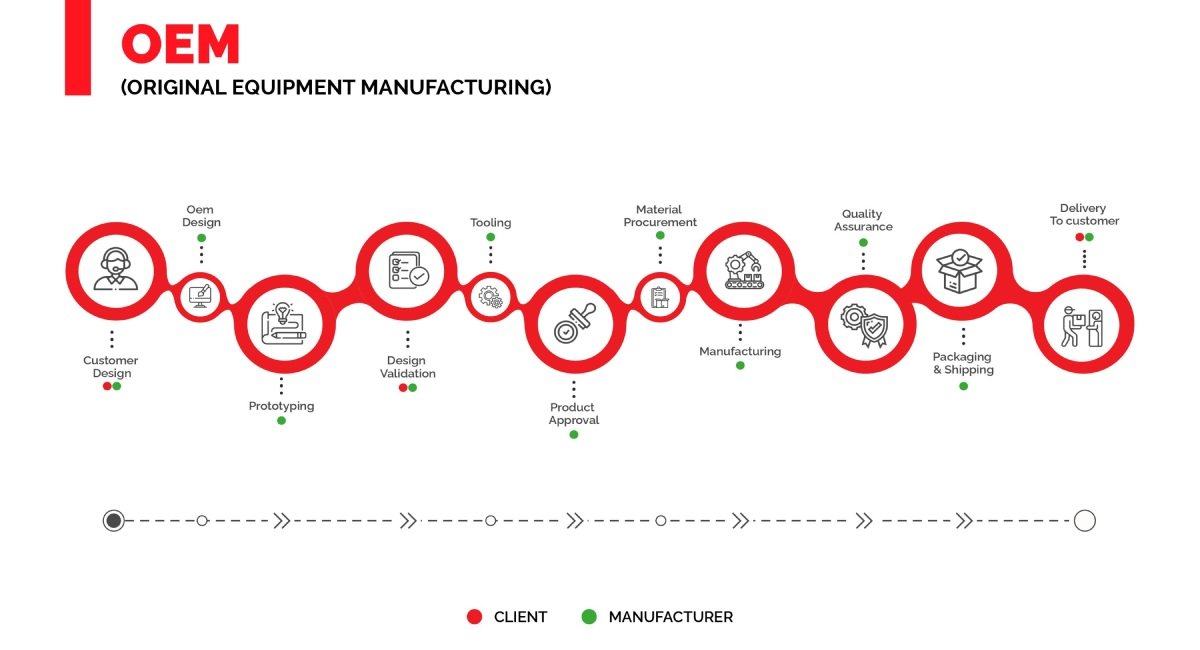

How to Manufacture a Product in Vietnam: A Step-by-Step Guide

Manufacturing a product in Vietnam can be a complex endeavor, but following these steps will simplify the process.

Step 1: Prepare Your Product Design and Specifications

The first step in making a product in Vietnam is the design phase.

Use Design for Manufacturing (DFM) procedures to create all the technical documentation the manufacturer will need. This will generally include:

- 3D CAD models

- 2D prints showing part tolerances and materials

- Bill of materials listing all the components and parts required for the product.

Factories can help with some of this work if they are paid, but generally, most manufacturers will have pretty limited design capabilities unless you are looking at minor changes to existing products. Design or product development firms can help with a lot of this, though you have to expect that there will be a process of localization – translating your original requirements to things that can be sourced and produced locally (changing hardware from imperial to metric for example).

Step 2: Build a Quotes Package

The next step is to get an estimate for the cost of production.

This is usually referred to as a Request for Quotation (RFQ) package. It should specify the delivery of all necessary technical drawings, material quality requirements, the amount of materials needed, packaging needs (labels, certifications etc.), any expectations you have for supplier testing or quality control beyond normal incoming quality inspection.

These details will allow manufacturer to provide detailed and accurate quotes for your production runs. They also improve transparency between you and the manufacturers, since they establish clear operational, material, and labor cost estimates, avoiding any surprise expenses or cost runoffs after the contract has been signed.

RFQs also help set up clear boundaries, expectations, and budgets early in the process.

Step 3: Identify Potential Candidates

Instead of sending your RFQ to every company you can find, narrow down a list of the most suitable candidates. This will avoid wasting time fielding quotes from, say, textile manufacturers who are not equipped to handle your injection molding project.

Start by looking for manufacturers on sites like Alibaba, the Global Sources Vietnam Fair, the Vietnam Chamber of Commerce, and other B2B platforms. You can also check out industry directories, trade fairs like the Vietnam Expo, or use a database dedicated to the type of manufacturer or supplier you want.

Another great option is working with agents or consultancy companies that specialize in linking companies with Vietnamese manufacturers. They will do the legwork and provide you with a list of potential candidates you can work from. They also be aware of a factory’s reputation, its reliability, and its overall business practices, all of which can help you avoid headaches in the long run.

In any case, always reach out to multiple manufacturers. Even if one company stands out as the most obvious choice, comparing different offers will help you determine which provides the best balance of cost savings and quality output.

Step 4: Send RFQs and Sort Manufacturers

Once you have compiled a list of potential manufacturers, it’s time to send out your RFQs. How each manufacturer responds will help you decide which one ones are worth considering.

Here are some things to look for in their responses:

- Clarity: Clear communication shows the company understands what you’re asking and increases the likelihood that they’ll be able to deliver it. If their response is unclear, this could indicate potential problems in the long run.

- Detailed Pricing: Transparency about costs is a sign of a trustworthy manufacturer. If there are hidden fees or unclear pricing structures, you may risk being paying unfair prices or being overcharged through unexpected fees.

- Responsiveness: If a company responds quickly and provides regular updates, this is a sign that they value client and customer satisfaction and are more likely to keep you posted through the production process.

- Information Security: If you’re dealing with sensitive intellectual property, look for a company that is willing to sign a Non-Disclosure Agreement (NDA). This will allow for legal protection for both sides while protecting any industrial drawings needed for the RFQ of the company.

Step 5: Shortlist and Evaluate Final Candidates

Now that you’ve narrowed down your options, you’ll need to pick out the best manufacturer for your needs. We recommend creating a scorecard so you can accurately and objectively weigh the pros and cons of working with each manufacturer.

Some criteria to include on your scorecard should include:

- Manufacturing Capabilities: Can the manufacturer actually produce the product you want and to the scale you want it? Some manufacturers are fantastic at small scale, but struggle to produce runs with 1,000 units or more.

- Quality Management Systems: These are mostly governed by the International Organization Standard (ISO). Compliance with these indicates whether or not the manufacturing facilities meet a reasonable baseline for quality, safety, and efficiency.

- Previous Clients and Projects: Gauge a manufacturer’s capabilities by evaluating their previous completed projects and clients. Have they completed projects on a scale similar to yours? Do they have repeat business from high profile clients?

- Communication and Transparency: Communication is key. If the manufacturer communicates poorly or is not transparent about its practices, you’re more likely to run into issues and struggle to get them resolved.

- Sample Reviews and Audits: Having a sample made from your design gives you a good idea of the manufacturer’s quality standards. An audit might also be necessary to confirm that the facilities actually meets your standards. You can visit the factory or send a representative to inspect conditions on the production floor.

Step 6: Launch Your Project

Once you’ve selected a manufacturer, you’re ready to launch your project.

This will typically follow four cycles:

- 1. Prototyping/Sampling: This is the phase where your product concept is put to the test. Allow the manufacturer time to process the prototype, figure out how it can be made with their equipment, and then review the sample to see if it is made to your specifications.

- 2. Manufacturing Contract: Once the prototype is produced and sampled, you will need to draft and sign a manufacturing contract that covers all legal expectations, payment terms, quality control responsibilities, penalties, and other pertinent factors. If you don’t have an in-house legal team, hire a lawyer familiar with local, international, and industrial law to write and review the terms before signing.

- 3. Pilot Production: This phase tests out whether or not the manufacturer can produce the product at scale. This is when early issues are caught and corrected before moving to a full production run.

- 4. Final Product/Quality Assurance: The final step will be making the final version of the product, which is ready to be shipped to consumers. Be sure to institute quality control processes to check for defects or issues before sending the products to retailers and customers.

An Emerging Manufacturing Powerhouse

Manufacturing in Vietnam is a great way to bring quality, cost-effective products to market. The process is similar to the one you would follow with contract manufacturing in any country: clear communication, good documentation, and extensive vetting of suppliers and manufacturers.

For the best results, having a local presence or third-party support can ensure that everything is carried out to your specifications, while easily resolving issues that may develop throughout the process.

FAQs

Q. Is Vietnam Affected by Trade Tariffs?

Yes, Vietnam is still affected by trade tariffs. However, Vietnam has been subject to lower export tariffs than China. The country also benefits from a number of Free Trade Agreements that mitigate or offset costs caused by tariffs.

Q. Are Labor Costs Lower in Vietnam Than Other Countries?

Yes. One of the primary reasons Vietnam is selected for manufacturing is that it is very cost effective in terms of labor. Vietnam’s low cost of living and wages that are approximately half those of workers in China make it an affordable option for manufacturing.

Q. What Type of Products Can Be Produced In Vietnam

Vietnam primarily produces electronics, textiles and apparel, footwear, automotive components , and other types of machinery. While there are plenty of manufacturers and suppliers covering other industries, these are Vietnam’s main export categories.