How to Choose the Right Box Build Assembly Manufacturer

- Introduction

- Key Takeaways

- What Does a Box Build Assembly Manufacturer Do?

- The Key Factors to Consider When Choosing a Manufacturer

- Local Vs. Overseas Box Build Manufacturers

- Questions to Ask Before Hiring

- Common Mistakes to Avoid

- Summary

Introduction

Box build assemblies are complicated products that need to be built to exacting standards. If you’re looking for a box build assembly specialist, you need to find one with the right capabilities for your project. They also need to be able to deliver on time, on scale and on budget. Different box build manufacturers have different expertise, production capabilities, skill levels and costs.

In this guide, we’ll tell you all the important things you need to know about how to assess box build assembly manufacturers.

Key Takeaways

- Do not assume that all box build assembly manufacturers are the same. Different manufacturers have different skills and experience.

- It often pays to choose a manufacturer with experience in your industry.

- Skilled manufacturers will be able to assist with design, troubleshoot issues and offer assistance with regulatory compliance.

- Good production management, supply chain management and quality control and testing are crucial skills for a box build assembly manufacturer.

Table of Contents

What Does a Box Build Assembly Manufacturer Do?

Box build assembly manufacturers specialize in manufacturing box build assemblies.

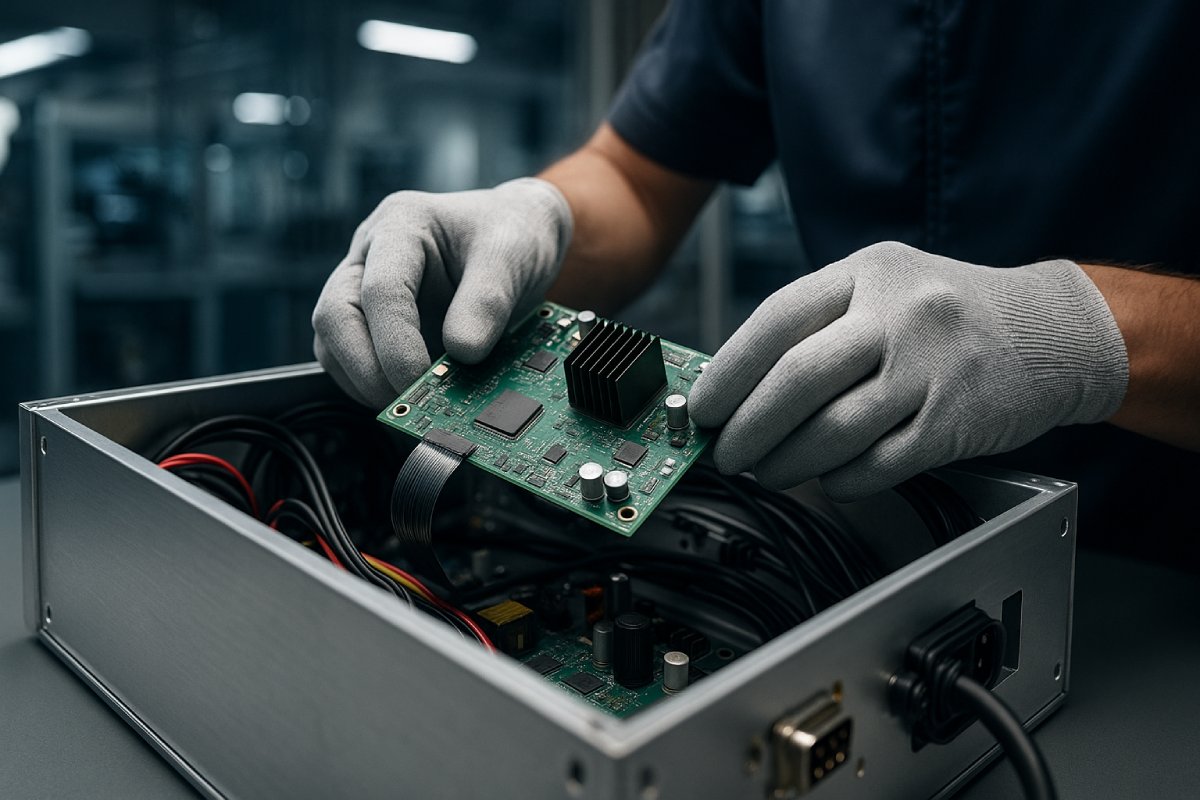

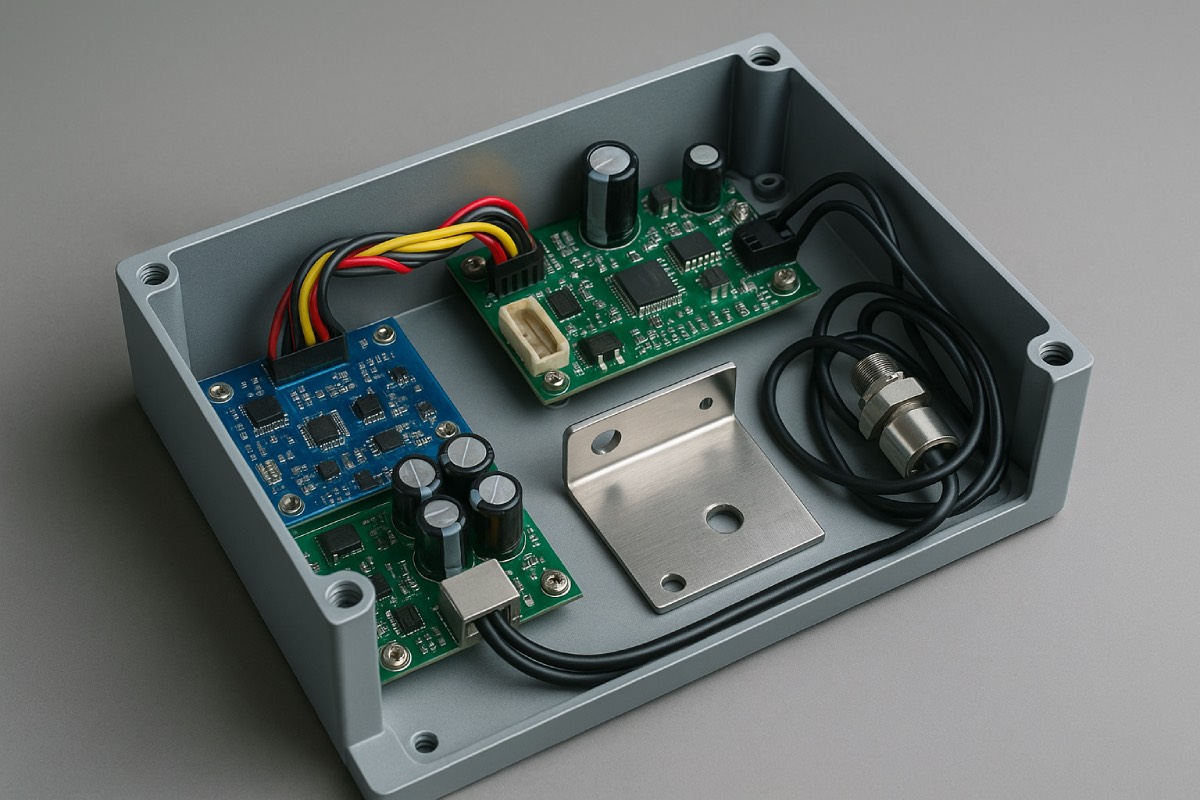

A box build assembly is an electronic assembly in which the components are assembled inside a purpose-built enclosure (box). Box build assemblies are complex, compact units that can incorporate many components, including printed circuit boards, cables and a huge range of other possible electronic, electrical and mechanical components.

They are built as complete single units that are ready for use once manufactured. They can either be a finished product in themselves or they can be integrated with other components into a larger product or installation.

Box build assembly is also referred to as ‘system integration’.

In-House Production vs Contract Manufacturing

Box build assembly is a specialist and often challenging field of manufacturing. Box build assemblies must:

- Meet a wide range of dimensional and mechanical requirements

- Incorporate many different components

- Perform a wide range of functions

- Be built to operate in many environments

Often, they also need to be built to meet regulatory requirements.

Box build assembly is normally handled by specialist box build assembly manufacturers. OEMs and brands and companies in a huge range of industries all outsource to box build assembly specialists.

The process of manufacturing box build assemblies is very difficult to manage in-house. It requires a large upfront investment, a long setup time, and it needs highly skilled engineers and production workers. Meanwhile, specialist companies can complete work quickly, to a higher standard and for a lower price.

The Key Factors to Consider When Choosing a Manufacturer

If you’re looking for a box build assembly manufacturer, it will pay to choose carefully. As well as being challenging to manufacture, box build assemblies are often high cost units that perform a critical role.

Different box build assembly manufacturers have different areas of expertise. They also offer different skill levels and capabilities as well as different prices, production volumes and lead times.

In this section, we’ll look at the most important factors to consider when comparing box build assembly manufacturers.

Experience and Industry Expertise

It is often very beneficial if you can hire a manufacturer with experience manufacturing for your industry. In some industries, this is critical.

Firstly, manufacturers with industry experience may be experienced with the production materials and components your box build will be made with. This can help to speed up and simplify production as well as ensure good standards of work. Some manufacturers will also be able to help with component and material selection.

Following manufacturing, industry knowledgeable manufacturers may be familiar with quality management procedures for products in your industry. Again, this can help with speed, simplicity and quality. In industries where regulatory compliance is important (such as medical, industrial and IoT), an experienced manufacturer may also be much better at handling regulatory compliance.

Manufacturing Capabilities

A skilled box build assembly manufacturer will be able to complete a wide range of complicated assembly processes and specialist manufacturing processes.

Box build assembly production often involves a range of manufacturing techniques. Processes such as stamping or sheet metal bending are needed for enclosure fabrication. Component assembly processes can also be complicated, such as with cable and harness assembly. Other specialist processes like potting, soldering or applying silicone or acrylic coatings might also be necessary.

What’s most critical is that the manufacturer can complete the processes you need for your box build assembly.

Supply Chain Management and Component Sourcing

Supply chain management is an important part of box build assembly manufacturing. Often, the established supply networks and expertise in administering inventories are significant advantages for specialist box build manufacturers.

Good supply chain management ensures uninterrupted manufacturing and adherence to production schedules. Besides this, it also ensures good quality in raw materials and components as well as cost optimization. Bulk purchasing is often a significant advantage that specialists have. On top of these benefits, box build specialists may be able to handle issues like design changes without major disruptions.

Cost and Lead Times

You need a box build assembly manufacturer that can complete production within your budget and timeframe.

When it comes to price, be aware that you may need to take into account hidden costs like tooling, testing, compliance or shipping. Larger orders also typically come at a lower price per unit.

Be aware that lead times can end up changing. Some unexpected factors that can affect lead times are prototyping and design alterations, component availability and any need for testing or certification. It’s also always a good idea to account for unexpected delays on top of your normal schedule.

Manufacturers located geographically closer will normally be able to complete production more quickly, if you need fast production.

A common pitfall to avoid is choosing the cheapest manufacturer. Often, low upfront costs come with quality issues or unreliable delivery.

Customization and Engineering Support

The quality of engineering and customization support you get with a box build assembly is important. You need a manufacturer with the technical expertise to produce your box build.

All box build assemblies have unique requirements. Check that your manufacturer can handle important issues you need to address with your box build. You might need a unique custom enclosure manufacture, a unique PCB layout or specialist programming, testing, and debugging for skills firmware integration, for example. They should also be able to identify and troubleshoot design or quality issues.

It’s also very beneficial if your manufacturer can offer design for manufacturability (DFM) support. With DFM support, a manufacturer will be able to evaluate designs and improve them to make manufacturing more efficient and to reduce costs.

Quality Control and Testing

Testing and quality control is crucial in box build assembly. There are many parts and components and also many stages of production. Testing and quality control usually has to be completed at various different stages. There are also many different quality control and testing procedures that need to be carried out, often requiring specialist knowledge.

For example, complicated electrical components or software may need to be tested.

A good manufacturer will have rigorous functional, environmental, and electrical testing as well as procedures for traceability and defect tracking.

Certifications and Regulatory Compliance

You might need to hire a box build assembly manufacturer that can handle certifications and regulatory compliance to ensure market access.

In most cases, you can check with your manufacturer that they are able to handle the certifications and regulations that apply to your product. Box build specialists may also be able to help you understand certification and regulatory requirements or to adjust designs to ensure compliance.

Some standards you might need to comply with are IPC-A-610 (electronics assembly) and industry-specific regulations like UL, RoHS and REACH.

Local Vs. Overseas Box Build Manufacturers

Most companies hire a box build assembly manufacturer based overseas. Most box build assembly manufacturers are based in Asia, with China having the majority share.

Overseas manufacturers are lower cost, due to lower labor costs and lower production expenses. They also have access to large-scale production facilities, enabling mass production. On top of this, overseas manufacturers have significant expertise and an extensive range of capabilities.

Overseas manufacturers do often have longer lead times and can face potential logistical difficulties. Weaker IP enforcement can also be an issue. If you need fast lead times and are concerned about IP protection, then it might be better to hire locally. Communication may also be easier with a locally based manufacturer.

The following table provides a summary of the trade off between local and overseas box build manufacturers:

| Factor | Local Manufacturers | Overseas Manufacturers |

|---|---|---|

| Cost | Higher labor and operational costs | Lower production costs |

| Lead Time | Faster turnaround (usually, weeks) | Longer shipping times (usually, months) |

| Communication | Easier due to time zone alignment | Potential language/response delays |

| IP Protection | Stronger legal protections | Higher risk of IP theft |

| Scalability | Limited to regional capacity | Access to large-scale production |

Questions to Ask Before Hiring

Here are some good questions to ask a box build assembly manufacturer before you hire them:

Relevant Experience and Capabilities

- Do you have experience manufacturing for my industry?

- Do you have experience in manufacturing products similar to mine?

- Can you share case studies or past projects similar to mine?

- Do you provide a complete turnkey service?

- What’s your IP protection policy?

Production Management

- Do you offer prototyping and small-batch production before mass manufacturing?

- How do you handle component shortages, obsolescence and other supply chain risks?

- Can we approve your suppliers?

- Do you provide DFM support?

- How do you handle design alterations?

Quality Control, Testing and Compliance

- What quality control and testing procedures do you follow and what certifications do you have?

- How do you perform quality control during production?

- Can you assist with regulatory compliance?

- Do you provide test reports and documentation?

Costs and Lead Times

- What’s your pricing structure?

- What are your average lead times and production capacity capabilities?

- Can you handle urgent orders?

- What’s your capacity for scaling production if demand increases?

Common Mistakes to Avoid When Choosing a Box Build Manufacturer

Here are some common pitfalls to avoid when hiring a box build assembly manufacturer:

- Choosing purely based on cost instead of capabilities and reliability

- Not verifying experience with similar products

- Skipping prototyping and DFM reviews

- Not discussing IP protection

- Ignoring certifications and compliance

- Overlooking communication and support availability

- Not considering scalability for future production growth

- Underestimating lead times

Summary

It’s important to be aware that box build assembly is a complicated area of manufacturing. Different box build manufacturers offer different areas of expertise, competencies and production facilities. They also offer different prices, production volumes and lead times.

Make sure you carefully examine any box build assembly manufacturer before you hire them.

The most important factors affecting selection are:

- Experience and industry expertise

- Manufacturing capabilities

- Supply chain management and component sourcing

- Cost and lead times

- Customization and engineering support

- Quality control and testing

- Certifications and regulatory compliance

With the right box build manufacturer, you will be able to produce high-quality box build assemblies on time and on budget.