ODM, OEM, CM – Which Type of Manufacturer Should You Pick for Your Project?

- Key Takeaways

- ODM, OEM and CM Manufacturers

- What Do the Terms OEM, ODM and CM Mean?

- The Basic Differences Between ODM, OEM and CM Manufacturing

- An In-Depth Look at Manufacturer Types

- Original Design Manufacturer (ODM)

- Original Equipment Manufacturer (OEM)

- Contract Manufacturer (CM)

- Other Contract Manufacturer Types

- Which Manufacturer Type is Right for You?

- Frequently Asked Questions

Introduction

When choosing a contract manufacturer for your product, you’re likely to come across acronyms such as OEM, ODM, and CM. Each of these represents a different model for outsourced manufacturing, and what they mean can have a significant impact on your control over the product, the production process, and your intellectual property.

Choosing the wrong supplier can result in frustration, months of time gone to waste, and significant expenses. So, let’s go over each type to help you figure out which is the best option for your business.

Key Takeaways

- OEM is a manufacturing model in which the customer supplies product designs but relies on the manufacturer’s specialized equipment, category expertise, and established supply chain.

- Under ODM, the manufacturer uses their own designs, saving the customer the trouble and expense of designing the product from scratch.

- Contract manufacturing provides a high level of customizability, but requires the customer to invest in custom tooling and design of a production process.

- CM offers the highest level of IP protection, allowing the customer to retain rights over all aspects of the product and design.

- ODM gives customers the fastest time to market, but with minimal product differentiation.

Table of Contents

- Key Takeaways

- ODM, OEM and CM Manufacturers

- What Do the Terms OEM, ODM and CM Mean?

- The Basic Differences Between ODM, OEM and CM Manufacturing

- An In-Depth Look at Manufacturer Types

- Original Design Manufacturer (ODM)

- Original Equipment Manufacturer (OEM)

- Contract Manufacturer (CM)

- Other Contract Manufacturer Types

- Which Manufacturer Type is Right for You?

- Frequently Asked Questions

ODM, OEM and CM Manufacturers

These acronyms describe various business models for third-party manufacturing:

- OEM – Original equipment manufacturer

- ODM – Original design manufacturer

- CM – Contract manufacturer

Each of these is fundamentally different, particularly in terms of how much responsibility the manufacturer takes for design. A manufacturer may also offer all three types of services.

Confusingly, the term “contract manufacturer” is used in two distinct ways. In some cases, it’s used as an umbrella term to refer to any manufacturer used to outsource production. In other cases, it’s used to refer to one specific type of outsourcing manufacturer. But don’t worry, we’ll clear all that up in a moment.

What Do the Terms OEM, ODM and CM Mean?

Here’s a quick breakdown of how these manufacturing models work.

Original Design Manufacturer (ODM)

Under an ODM arrangement, the product design is owned by the manufacturer. The customer can either request slight adjustments to the design or simply label the product with their brand or logo. ODM products are also referred to as “white label” or “private label” products.

- Intellectual Property: The design, tooling and other IP belong to the supplier.

- Example: A company wanting to sell a line of blenders buys an existing product from a supplier specializing in kitchen appliances. To make the product distinct from the competition, the customer has the manufacturer customize it with their company’s color scheme, logo, and slight modifications to the overall design.

Original Equipment Manufacturer (OEM)

With OEM, a new product is developed by the manufacturer based on a design from the customer. However, the production will rely on the supplier’s category expertise, specialized equipment, and established supply chain.

- Intellectual Property: At least a portion of the IP belongs to the customer, usually as long as they are paying for the development, tooling and their contracts are in order.

- Example: A company wants to create an entirely new design for their line of kitchen blenders, including unique functional features and technical specs. They contract with an OEM supplier that has experience manufacturing kitchen appliances to create custom tooling and bring the customer’s design to production.

Contract Manufacturer (CM)

In contract manufacturing, the customer has full ownership of the design and bill of materials (BOM). The manufacturer is solely responsible for manufacturing based on the customer’s drawings and adhering to their requirements, not for the product design or development.

Pure contract manufacturers do not have their own product range or product specialities. Instead, they focus on providing manufacturing services to customers in a wide range of categories.

- Intellectual Property: The IP clearly belongs to the customer, as they are the ones conducting product design, development, and evaluation.

- Example: Foxconn produces the iPhone, but is only responsible for the manufacturing side of the business. Design and development comes entirely from Apple (hence the “Designed in California” label on many of the company’s products). In this case, Foxconn is not adapting an existing smartphone design or using their pre-established architecture, but simply handling the manufacturing based on Apple’s detailed specifications.

The Basic Differences Between ODM, OEM and CM Manufacturing

Here’s a quick overview of the fundamental differences between ODM, OEM and CM:

| Type of Contract Manufacturing / Criteria | ODM | OEM | CM |

|---|---|---|---|

| Intellectual property | Supplier owned | Partially customer owned | Fully customer owned |

| Product modification | Basic changes only (color, packaging, etc.) | The customer gives input on specifications | The customer defines specifications |

| Tooling | Belongs to the supplier | Usually only external design owned by buyer | Belongs to the buyer |

| BOM | Customer has little to no control | The customer has limited control or input | Fully controlled by the customer |

| Category specialization | Specialized in a certain category | Specialized in a certain category | Wide range of product categories |

A comparison of ODM, OEM, and CM manufacturing models

An In-Depth Look at Manufacturer Types

Looking at the main advantages and disadvantages associated with each type of manufacturer as well as some typical use cases may help you understand which type will better suit your business.

Original Design Manufacturer (ODM)

ODM products are cheap to produce and quick to get to market.

With the supplier handling most aspects of production, the customer only needs to focus on marketing and operations for the product launch. The factory should be able to produce and ship a functional product with little input from the hiring company.

Advantages of ODM

- Simplicity – Very little design or technical input needed because the product is already on the market and proven in use.

- Personalization – Products can be branded with the hiring company’s colors or logo. Small design alterations are also possible, such as changing accessories or parts like handles or buttons.

- Speed to Market – Even with branding and personalization, speed to market is much faster since products don’t need to be developed and tested.

- Reduced Cost – The manufacturer’s experience, developed supply chain and economies of scale all reduce costs for the customer.

- Lower Minimum Order Quantity Requirements – Minimum order quantities (MOQs) are often lower because suppliers produce the same product for multiple buyers.

Disadvantages of ODM

Minimal Product Differentiation – Because multiple products are made from the same fundamental design, market differentiation will be limited. Success will depend mainly on brand reputation or marketing, not product features.

Lack of Insight Into Production – The hiring company typically has little visibility into how production takes place, including the kind of quality control procedures that are followed.

Limited Supply Chain Flexibility – The buyer also has limited control over the supply chain and bill of materials. Usually, the manufacturer makes all choices for matters such as materials, parts and components, or even firmware or software design. ODMs will want to use existing relationships due to cost and cash flow advantages, which may compromise product quality or function.

Minimal Control over Intellectual Property – The product design belongs to the supplier, and they are free to sell the same product to other companies. Minor design improvements and tweaks also won’t be the buyer’s IP unless specifically stated in the manufacturing contract.

Typical ODM Customers

Home goods, low-end consumer electronics, LED lighting and household appliances are often manufactured by ODM suppliers. The same is true of simple, branded merchandise like t-shirts, mugs or phone cases.

Mature product markets often use the ODM model, as do industries where low cost and a quicker speed to market are more important than design or functional differentiation.

In some cases, complicated products are made by ODM manufacturers. Bicycles, for example, can be OEM or ODM. There are off-the-shelf options for low-cost online retailers and smaller brands. At the same time, there are also factories that produce custom designed models for higher-end brands.

When You Should Work with an ODM

The ODM model gives you a fast way to go to market without any heavy investments. It’s ideal for companies that are seeking speed and simplicity. However, it means giving up control over the manufacturing process and intellectual property rights, so those factors must be taken into consideration as well.

Original Equipment Manufacturer (OEM)

In the OEM manufacturing model, the customer takes responsibility for product design and work with a manufacturer that has experience in the relevant product category.

Advantages of OEM

- Product Customization – Using your own designs means you can create a product that stands out in the market. This product differentiation could allow it to fetch a higher price or drive increased demand.

- Speed to Market – While slower than an ODM, an OEM can manufacture products faster than a CM because of their established supply chain and experience making products in the same category. This allows the manufacturer to source parts, components, and materials quickly and set up production processes without delay.

- Lower Costs – An OEM’s established supply chain and efficient production processes reduce the overall costs of manufacturing, compared to working with a CM.

- Reduced Overall Involvement – Working with an experienced production partner may reduce the overall level of involvement required from the hiring company.

Disadvantages of OEM

- Slower and More Expensive than ODM Manufacturing – Speed to market and costs are less favorable compared to ODM manufacturing.

- Greater Investment, but Limited Control Over Production - An OEM project requires more input from the customer than working with an ODM manufacturer. The hiring company will need to create designs, monitor product development and invest in tooling and prototypes. Despite this additional involvement, the OEM will most likely still dictate the supply chain decisions, control much of production and limit the customer’s ability to direct the project in other areas.

- Intellectual Property Leakage - OEM suppliers often act as ODM suppliers for other buyers. In some cases, suppliers may take designs or elements from OEM projects and sell them within their own ODM products.

- OEMs May Become Direct Competitors – OEM manufacturers sometimes launch their own brands and become direct competitors to their former customers. The home appliance and consumer electronics markets are filled with OEM manufacturers selling their own line of consumer goods.

Typical OEM Customers

Consumer electronics brands like Vizio or Skullcandy are great examples of OEM customers. They have their own designs and technology, but use existing electronics manufacturers to make their products. Automakers that use an external supplier for electronics or electrical components (such as a car radio or light indicators) are also considered OEM customers.

Contract Manufacturer (CM)

Contract manufacturers generally aren’t focused on a single category the way ODMs and OEMs are. You can approach a CM with a product in a category the company has no previous experience with and they will design a production process from scratch. CMs typically don’t have their own business lines or intellectual property, and they don’t design new products. Instead, they simply offer manufacturing as a service to hiring companies.

The customer provides the design, and the contract manufacturer provides the labor, facilities and manufacturing know-how to produce that product.

Advantages of CM

- Product Customization – As with OEM manufacturing, you can approach a CM manufacturer with designs for a unique product that will be different from those offered by your competitors, allowing you to differentiate based on product features and quality.

- Greater Supply Chain Flexibility – Contract manufacturers are more likely to be willing to take consigned parts, work with customer-designated suppliers, provide greater detail on part specifications or otherwise be more transparent and accommodating with regards to the supply chain.

- Control Over Subsystem and Subcomponent Manufacturing – Contract manufacturers are more likely to allow the customer to have control over the cost, quality and lead time of subsystems and subcomponents.

- Complete Ownership of Intellectual Property Rights – Using a manufacturer that has no competing business greatly reduces the potential for conflicts of interest and loss of intellectual property.

- A Simpler Business Relationship – Without the complications over tooling and IP rights that can arise with ODM and OEM manufacturers, working with a contract manufacturer tends to be much simpler.

Disadvantages of CM

- Greater Investment in Product Design and Development – The hiring company is fully responsible for the design and development of its products, which can time consuming and expensive.

- Tooling and Manufacturing Process Development – To meet the customer’s needs, the manufacturer will need to develop a production system from scratch. This may include the development of tooling or system architecture, which can be costly and time consuming.

- Longer Lead Times – Contract manufacturing comes with the slowest lead time because product designs, the supply chain and production processes have to be developed from scratch.

- Higher Costs – The higher level of input required when working with a contract manufacturer also leads to higher costs.

Typical CM Customers

Products that have a high level of complexity or are sold in niche markets are often made through contract manufacturing, due to the lack of OEM and ODM options. Entrepreneurs or brands creating completely unique products will also have to rely on contract manufacturers.

Companies will also go the CM route when they want more differentiation in the marketplace. As will customers that are sensitive about their intellectual property rights and want to use a manufacturing model that allows them to retain full ownership.

While any product can be manufactured under the CM model, it is commonly used in the automotive, consumer electronics, industrial equipment and motorcycle/ATV industries.

When You Should Work with a CM

Contract manufacturing is a good choice when lead times are less important and budgets can accommodate the customization needed to make it happen. It is especially useful where there is potential to make higher profits by bringing a unique product to market.

It’s often the better option when intellectual property needs to be protected.

Other Contract Manufacturer Types

ODM, OEM and CM are the most common models for outsourcing production, but there are other approaches specific to electronics manufacturing.

Electronics Manufacturing Services (EMS)

EMS offers a comprehensive range of services in electronics manufacturing. Apart from making products that are ordered by OEMs, EMS suppliers also offer services such as product design, manufacturing process design, assembly and logistics.

EMS companies can operate on a massive scale –manufacturing products like Microsoft’s Xbox, for example.

Contract Electronics Manufacturer (CEM)

CEMs typically support OEMs and other manufacturing companies by providing partial or whole electronics manufacturing services based on requirements set out by a hiring company. CEMs are often used for products that must meet stringent requirements, such as those used in the medical, automotive or defense industries.

Design House

Design houses usually offer a full range of electronics design services for both hardware and software, across a wide range of products and markets. They have been a crucial part of the contract manufacturing process for high-tech consumer electronics like smartphones.

Which Manufacturer Type is Right for You?

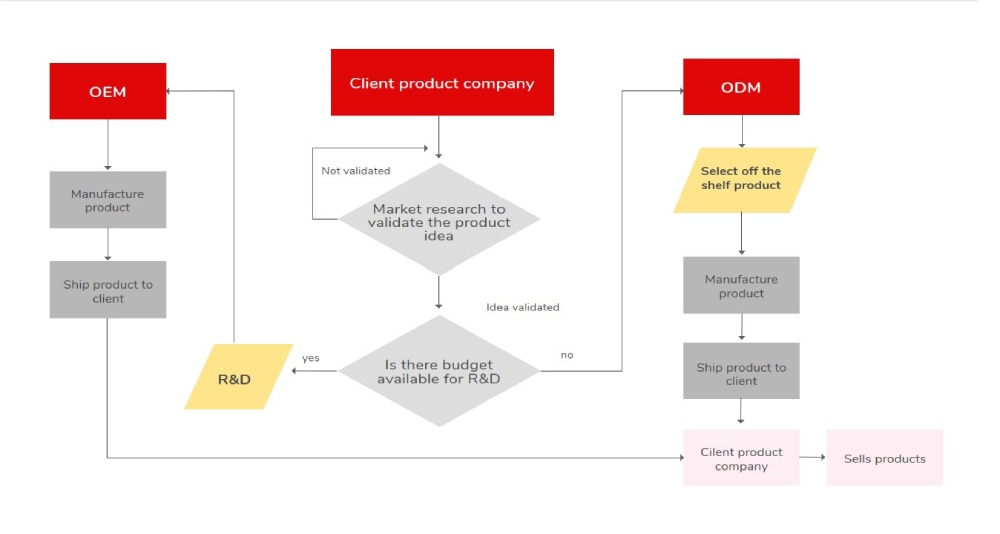

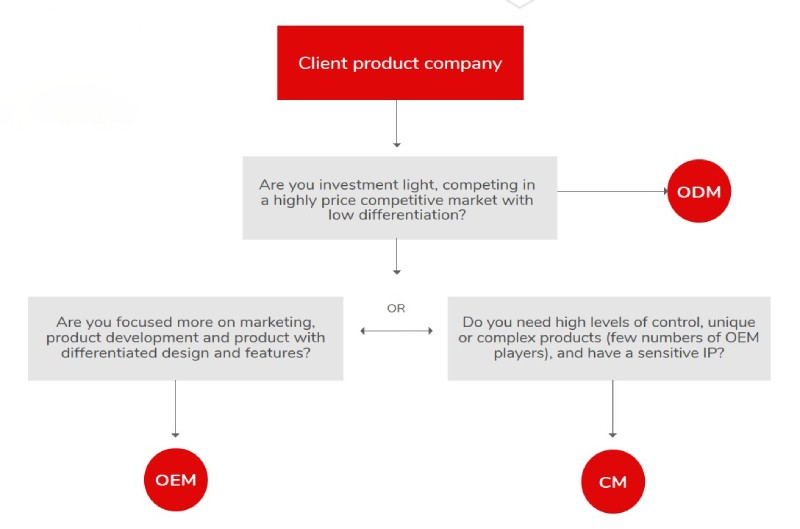

At a basic level, choosing the right manufacturing model is relatively simple. The following flowchart summarizes the key considerations you should run through when making this decision:

While the choice is simple in the abstract, you may have to look at your company’s position in more depth before making a final decision. Here are some factors to weigh when assessing your position and your manufacturing needs:

- Your industry and business model

- How you handle marketing, product development and differentiation

- Your preferred level of control over the manufacturing process

- The uniqueness and complexity of your product

- The level of sensitivity of your intellectual property

- Your long-term objectives and the kind of partnership you want to develop with a manufacturer

As an example, let’s compare an Amazon retailer and a branded company and the factors that might come into play when choosing the right model.

| Amazon Retailer | Branded Company |

|---|---|

| Many products | Fewer products |

| Speed to market critical | Balance between speed, pricing and differentiation |

| Low design and development resources | High design and development resources |

| Low level of investment capital | High investment capital |

| Lower level of differentiation | Higher level of differentiation |

| Low level of IP | Sensitive IP |

| Weak brand differentiation | Strong brand differentiation |

Amazon vs Branded Company Comparison

Based on these preferences, we can assume that the Amazon retailer will prefer using an ODM, since it is participating in a market with high price competition and low differentiation.

The branded company, on the other hand, would likely choose an OEM or CM partner to gain a higher level of control over the production, more control over intellectual property and to make a product with more substantive differentiation.

Conclusion

- ODM – Fastest route to market without needing to invest in product design and development. However, you will not own the intellectual property for your product or have any control over the manufacturing process.

- OEM – More control over the IP and manufacturing process. Can make a more unique product, but requires investment in design and development.

- Contract Manufacturing – Highest level of product customization and control over the supply chain and manufacturing process. However, your input will be highest with this type of manufacturer.

| Features | Manufacturing Model | ||

|---|---|---|---|

| ODM | OEM | CM | |

| Provides ready-made products with customization options | ✓ | ||

| Specializes in certain product categories | ✓ | ✓ | |

| Customer provides input on design/product specifications | ✓ | ✓ | |

| Produces product from scratch, based on customer design requirements | ✓ | ||

| Offers greater supply chain transparency and consigned component options | ✓ | ||

| Gives greater transparency on subassembly and component specifications, cost, quality, etc. | ✓ | ||

| Buyer needs to invest time & money in product design, research and testing | ✓ | ✓ | |

| Gives customers a say in the choice of material supply | ✓ | ||

| Assumes manufacturing liability | ✓ | ✓ | ✓ |

| Assumes product design liability | ✓ | ||

| Provides customer control over product intellectual property | ✓ | ✓ | |

A comparison of ODM, OEM and CM manufacturing models.

Frequently Asked Questions

What Does OEM Stand For?

OEM stands for original equipment manufacturer. It is a manufacturing model in which a factory develops a new product based on designs supplied by the hiring company.

Under an OEM arrangement, the hiring company can benefit from the supplier’s category expertise, established supply chain and prior experience making products in the same category.

Learn more: What is an Original Equipment Manufacturer (OEM)?.

What Does ODM Stand For?

ODM stands for original design manufacturer. It is a manufacturing in which the hiring company orders a product to be made using a design owned by the supplier. The customer can either tweak the design slightly or simply buy a product straight off the shelf and label it with their logo or branding.

Learn more: What Is an OEM, ODM, and JDM?.

What is an Example of an OEM?

Many microchip manufacturers operate as OEMs. Companies making a product through these suppliers will focus on designing the chip architecture and marketing the produce, while the actual manufacturing is done by a third-party microchip factory.

Learn more: Why the Right OEM Relationship Leads to Powerful Mobile Solutions.

What is an Example of an ODM?

An ODM can be a manufacturer that specializes in producing consumer electronics for various brands and companies. A hiring company might buy an item like a USB charger from an ODM supplier, relying on that manufacturer’s existing design. The company can adjust the design in superficial ways (color scheme, logo, small modifications to the outer shell) to make it visually distinct and sell it under their brand name, but the underlying components will be entirely the ODM’s design.

What is the Difference Between OEM and ODM?

Under OEM, a new product is manufactured by a factory that has the equipment and infrastructure to create products in a specific category, but the designs will be supplied by the hiring company.

With ODM, on the other hand, the manufacturer makes use of their own designs to put together a product for the hiring company. In this case, the product is functionally similar to the ones the ODM produces for other customers, with only brand, logos, and slight alterations to differentiate it.