around the world

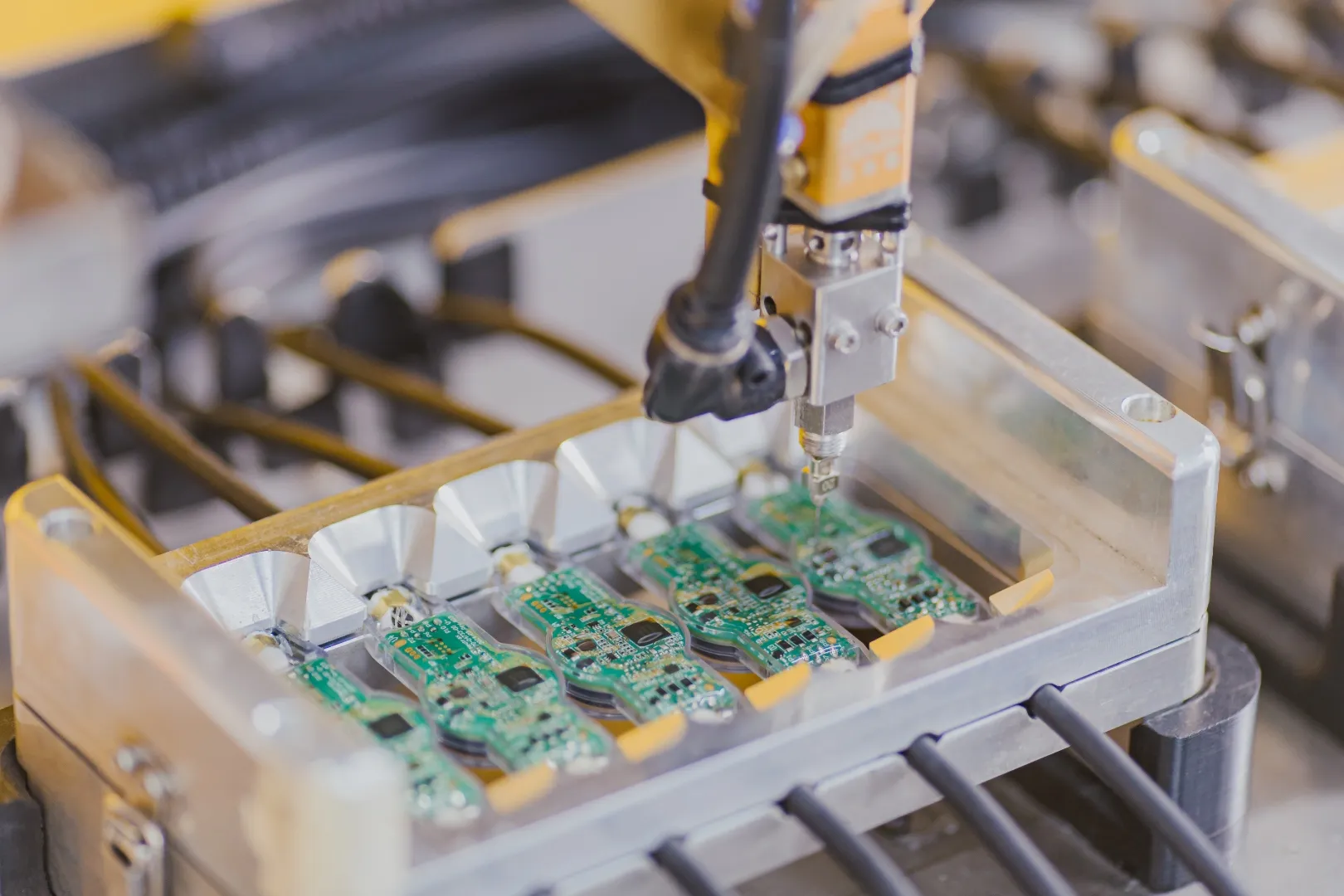

Electronics Manufacturing and Assembly

Komaspec is your partner for high-mix, medium- to high-volume custom electronics manufacturing. Our Vietnam electronics factory helps innovative brands and OEMs move from idea to repeatable electronics assembly with speed, reliability, and tight process control.

}

}

}

}

}

}

Who We Do It For

Supporting Businesses from Prototyping to Mass Production

Industries & Businesses We Serve

Komaspec partners with companies at every stage of growth, providing scalable manufacturing and assembly solutions tailored to your needs.

- Startups & Innovators – Accelerate product development with rapid prototyping, DFM (Design for Manufacturability) support, and small-batch production—ideal for validating new concepts and preparing for launch.

- Growing Businesses & SMEs – Scale up confidently with flexible MOQs, cost-effective manufacturing, and robust quality assurance as your business expands and enters new markets.

- Enterprises & OEMs – Rely on Komaspec for large-scale production, turnkey assembly, integrated supply chain solutions, and global logistics to meet demanding timelines and volume requirements.

Who We Are

Your Partner in Precision Manufacturing

Founded in 2005, Komaspec has grown into a multinational contract manufacturer with facilities in Vietnam, China, and Mexico. Our teams bring engineering depth, vertically integrated production, and rigorous quality assurance to every project.

-

High-Precision Manufacturing Advanced engineering and smart factory technology ensure top-tier quality, with real-time monitoring from quote to shipment.

-

Fast & Scalable Production Flexible manufacturing adapts to demand with high efficiency, producing over 6 million finished products annually.

-

Optimized Supply Chain Streamlined global logistics and strategic partnerships across three countries help reduce costs and accelerate delivery.

-

Uncompromising Quality Control A rigorous inspection process ensures reliability and consistency for customers in industries such as automotive, agriculture, mining, and consumer goods.

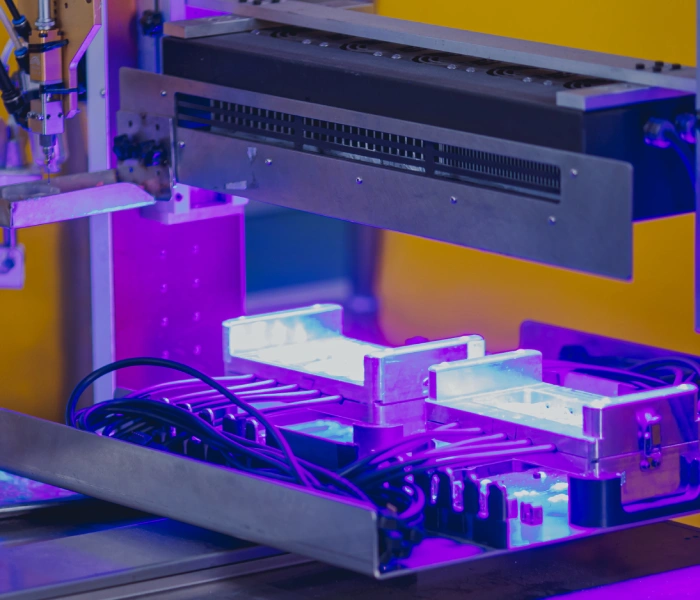

Turnkey Support for Custom Electronics & Electromechanical Products

Komaspec’s Vietnam production facility has extensive in-house manufacturing and support services to help bring electronic products to market.

Contract Manufacturing

Contract Manufacturing

Turnkey builds with one accountable manufacturing partner.

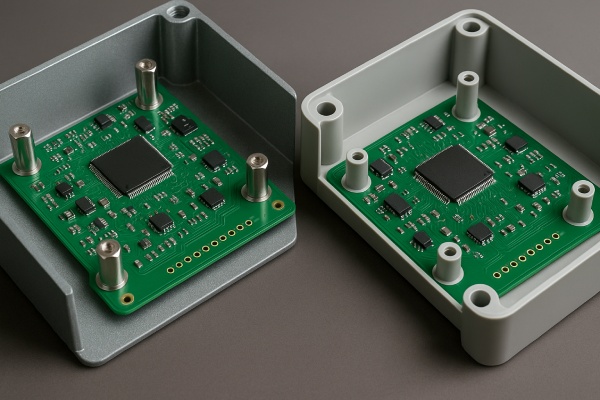

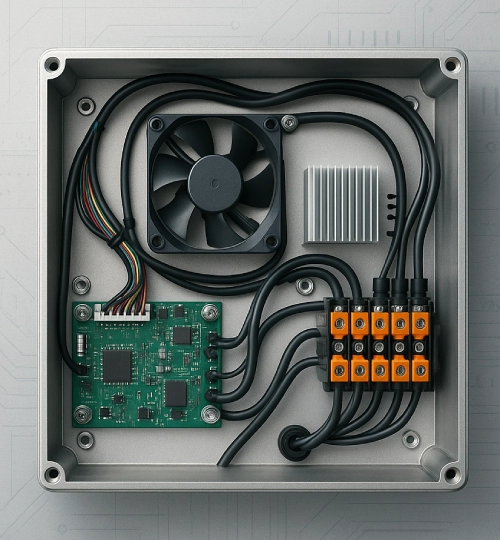

Assembly

Assembly

Electronics, electromechanical, and box-build integration.

Sheet Metal Fabrication

Sheet Metal Fabrication

Enclosures, frames, and brackets manufactured in-house.

Plastic Injection

Plastic Injection

Custom housings and components with tight tolerances.

Stamping & Machining

Stamping & Machining

Precision metal parts to support assemblies.

Laser Cutting

Laser Cutting

Clean, consistent structural elements.

NPI

NPI

Prototypes and pilot runs to validate designs before ramp.

Inspection, testing, and traceability built into every step.

Electronics Manufacturing Process

A streamlined, step-by-step journey for electronics and electromechanical products

Where We Do It

Our Locations

Juarez, Mexico

1 20,000 SQF- Laser Cutting

- CNC Bending

- CNC Milling

- Assemblies

- Built-In Quality Management

- Digital Manufacturing

Guangzhou, China

4 110,000 SQF- Laser Cutting

- CNC Bending

- CNC Milling

- CNC Turning

- Welding

- CNC Tube Bending

- Stamping

- Plastic Injection

- Hardware

- Off-the-Shelf Part Procurement

- Assemblies

- Built-In Quality Management

- Digital Manufacturing

Haiphong, Vietnam

1 60,000 SQF- Laser Cutting

- CNC Bending

- PEM

- Welding

- Plastic Injection

- Hardware

- Off-the-Shelf Part Procurement

- Assemblies

- Built-In Quality Management

Testimonials

What Our Clients Say

FAQS

Answers to common questions about our electronics and electromechanical manufacturing services.

We assemble a wide range of products, including industrial electronics, box-builds, IoT devices, commercial appliances, and electromechanical systems that combine mechanical and electrical components.

Absolutely. Our systems are designed for flexibility, making us a strong partner for SMEs and specialized OEMs with diverse product portfolios.

Yes. Our vertically integrated capabilities cover electronics, sheet metal, plastic injection, and assembly — allowing us to deliver complete turnkey products.

Yes. Our engineering team provides DFM/A support and reverse engineering services to optimize products for manufacturability, performance, and cost efficiency.

es. Our 60,000 ft² electronics factory in Vietnam is dedicated to custom electronics manufacturing and assembly, and you can select it as your production site.

Ready to Bring Your Product from Concept to Production?

Work with Komaspec for expert engineering, in-house manufacturing, and turnkey assembly—all under one roof.