What is OEM vs Contract Manufacturing?

- Key Takeaways

- Introduction

- OEM (Original Equipment Manufacturing)

- Contract Manufacturing

- Comparing OEM vs Contract Manufacturing

- OEM vs. CM

- Examples of OEM and CM

- Conclusion

Introduction

Original equipment manufacturing (OEM) and contract manufacturing can be a source of confusion for many companies. Both are models for outsourcing production, but there are important differences between them.

Contract manufacturing is manufacturing-as-a-service. The customer provides all designs and specifications, while the supplier simply builds the product based on those details.

With OEM, the customer only provides a portion of the design and the supplier incorporates their existing components and expertise to create the finished product.

Neither model is inherently superior. Each has its unique benefits and drawbacks. It’s important for companies to evaluate both models and select the one that best meets their needs.

This article will help you do just that. We’ll take a closer look at the differences between OEM and contract manufacturing and help you figure out which one is the right choice for your business.

Key Takeaways

- OEM and CM are different models for outsourced manufacturing.

- OEM manufacturers offer specialized manufacturing infrastructure, design expertise, and pre-existing components to simplify production.

- Contract manufacturers offer manufacturing-as-a-service, which allows for greater flexibility and customization but requires more design input from the customer.

- With OEM, the manufacturer will typically retain intellectual property rights for some aspects of the design.

Table of Contents

OEM (Original Equipment Manufacturing)

OEM is a manufacturing model where the manufacturer develops a product that will be marketed under a different company’s brand name (a practice known as private label manufacturing).

Under this arrangement, a company approaches a manufacturer that specializes in a particular type of product and contracts them to produce a version of it for them. The company provides the design and specifications. There will often be custom tooling or new development work involved, but the OEM suppliers will develop the customer’s product on their existing production line.

Here's a typical rundown of an OEM scenario:

- A company that sells TVs approaches a manufacturer that produces TVs to manufacture their product.

- The company provides industrial designs and specs, such as size, picture quality, input/output ports, and internet connectivity.

- The manufacturer uses their existing facilities, tooling, machinery, and established supply chain to manufacture and deliver the product for the customer.

- The customer then sells and markets the product under their own brand.

Under this model, the customer owns the product and the rights to its design, and the name or brand of the manufacturer does not appear on the product or packaging.

However, because the manufacturer uses their existing product architecture, there is often a mix of intellectual property involved. While the customer owns the product design, the supplier may hold the rights to the design of some components or patents on innovations used in the product. This can cause some complications when moving production to a new manufacturer.

Advantages of OEM

- OEM manufacturers typically specialize in a specific product category, often resulting in higher-quality outputs.

- Manufacturers also tend to have established, reliable supply chains and direct access to relevant suppliers, leading to cost savings (due to economies of scale), faster product development cycles, and higher component quality.

- OEM enables companies to stipulate product specifications and retain design rights for the finished product.

- Working with an OEM allows companies to free up time, resources, and staffing so they can focus on other aspects of their businesses.

Disadvantages of OEM

- The customer depends entirely on the manufacturer for the product, so any issue with the manufacturer or their supply chain also affects the customer directly.

- The customer has less control over product design, component selection, and certain specifications than they do with contract manufacturing.

- One manufacturer often makes products for several companies. So while the design of these products may be unique, their performance will be similar, making product differentiation much harder.

- Quality control issues with components can affect all the manufacturer’s customers (for instance, a component failure in the early 2000s affected the products of several major brands, including IBM, Apple, HP, and Dell).

Contract Manufacturing (CM)

With contract manufacturing, a business contracts a manufacturer to produce and package a product on its behalf. Under this arrangement, the supplier is essentially building the product according to drawings and specs supplied by the customer. This means the customer is responsible for the design, while the factory is purely providing labor and manufacturing services.

Unlike OEM manufacturers, contract manufacturers generally do not specialize in specific product categories and do not have ready-made tooling or designs for their own product lines. Instead, they have facilities that can produce custom tooling to meet their customers’ needs. This flexibility allows companies to use CM to develop unique products or products where there is significant intellectual property.

In CM, a company could rely on a single manufacturer for every stage of product development, from design to delivery – an approach to CM known as turnkey manufacturing. Or they may opt for contract assembly, in which they rely on a manufacturer to assemble ready-made parts into a finished product.

Contract manufacturing scenarios vary greatly, but here’s a rundown of how it might look:

- A company develops a scooter and tests the design to ensure it functions as intended.

- They contract a manufacturer to produce the electronic components of the scooter, and another to create the outer casing and assemble the final product.

- In doing so, the customer takes on the responsibility of ensuring that the electronics manufacturer produces and delivers the components to the manufacturer tasked with completing the product.

- The second manufacturer delivers the product to the customer, who then sells it under their brand.

Advantages of Contract Manufacturing

- Contract manufacturing allows far greater control over all aspects of product design. The customer can specify down to the supplier and component level.

- Customers don’t have to rely on a single manufacturer for all aspects of product development. This makes it easier to swap out an unsuitable manufacturer or supplier at any stage of the process.

- Contract manufacturers are more flexible, since projects don’t have to fit within an established product line or strategy. This makes them a good option for new product development and small- to medium-sized businesses.

- The customer holds rights to the product design and product tooling. Intellectual property is far more clearcut than it is with OEM.

Disadvantages of Contract Manufacturing

- The customer has to invest more resources in design, design validation, technical drawings, and general product engineering.

- Product lead times are generally longer, as the tooling and product is being developed from scratch.

- Unless working with a turnkey manufacturer, dealing with multiple contractors multiplies the risks associated with product quality, supply chain disruption, and IP leakage.

Comparing OEM vs Contract Manufacturing

While OEM and CM are both forms of outsourced manufacturing, it’s important to get straight on the distinction between them. So, here are the major differences between the two models and what they mean for the companies relying on them.

Product Specialization

In OEM, manufacturers typically specialize in a specific product type or category, such as electronics, home appliances, automotive systems, or advanced medical equipment. This means the manufacturer will have existing tooling, approved vendors and components, specialized expertise, and their own components that can be included in the finished product.

Contract manufacturing provides more flexibility. Rather than specializing in a specific category, manufacturers will build based on the customer’s designs, without providing their own specialized components.

Customer Involvement

Contract manufacturing requires more input from the customer. When working with a manufacturer, you are responsible for the product design, specifications, and design validation.

Since OEM manufacturers are specialized in the product they’re making, they may have ready-made designs the customer can build upon, the tooling needed to get production rolling, a robust supplier network for components, and an existing quality control system for the product category. The manufacturer will often do much of the heavy lifting in the design phase (such as structural and electrical engineering), so the customer only needs to provide input on external design and the features they want.

Product Design and Tooling Rights

In CM, because the customer is responsible for the product design, they hold all the rights to it. Often, they will also hold the rights to the tooling, since it would be custom-made for their product.

In OEM, ownership over the design mainly depends on the agreement between the customer and the manufacturer. Typically, the manufacturer retains the rights to internal designs and tooling, while the customer owns the rights to external designs they developed, any custom tools or designs they paid for, as well as any new technology developed. Regardless of the details, the IP ownership will be mixed, which can create problems if there are conflicts between the customer and the manufacturer, especially if the customer wants to change suppliers.

Initial Investment in Product Development

Being product specialists, OEM manufacturers often have ready-made tooling for specific products that can be used when creating new designs. They may also have tooled, tested, certified, and cost-amortized components and product prototypes. These factors contribute to a lower initial investment from the customer.

With CM, the manufacturer will have to develop custom tooling, qualify component suppliers, conduct testing and certification – all of which will increase the up-front costs for the customer.

Product Development Timeline

OEM usually has a faster product development timeline than CM, since the manufacturer will spend less time on product design, prototyping, and material sourcing.

| Criteria | OEM | Contract Manufacturing |

| Product specialization | Synonymous with complex, specialized products | Cuts across a wide range of custom non-niche product categories |

| Customer involvement | Minimal customer involvement after design | The customer has some control over the manufacturing process |

| Design and tooling rights | Rights ownership varies, depending on the contract. Manufacturer and customer may share rights | Rights solely belong to the customer |

| Initial Investment costs | Lower initial investment costs due to existing designs and tooling | Higher initial investment costs due to new product tooling |

| Product development timeline | Faster product development due to readymade designs, functional prototypes, and established supply chains | Greater time spent in product design, prototyping, and procurement, leading to slower product development |

Table 1: Comparing OEM vs Contract Manufacturing Models

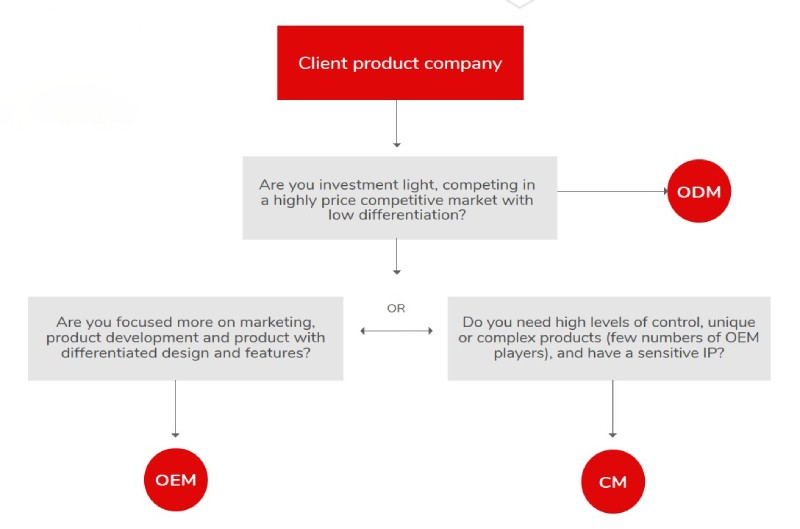

OEM vs. Contract Manufacturing: Selecting the Right Model for Your Business

Product type

If you want to manufacture a variant of an existing product with only moderate differentiation, OEM is often the better choice.

Likewise for high-volume, price sensitive products or production that require a high level of capital investment. This is why OEM is a popular model for household appliances, computers, and mobile phones. It’s much easier for customers to find a supplier that already has the capability to make these products than to pay for the infrastructure required to manufacture them.

Contract manufacturing is better suited for products where there isn’t a strong OEM supply base. This is often the case for medical products, mining equipment, and IOT devices.

Initial Costs

For more modest production budgets, OEM allows entry into the market at a lower cost, thanks to prefabricated tools, prototypes, and well-established supply chains.

IP Rights

If your intellectual property is limited to the product’s external design and a few of its features, OEM can be a suitable choice.

For products with more extensive or sensitive intellectual property, such as custom software, firmware, and innovative functions, CM will allow you to hold onto more of the IP rights.

Time to Market

If time-to-market is a critical consideration, or if the product is being updated on a regular basis (annually, for example), OEM is the better option, as it will shrink timelines.

Manufacturing Flexibility

In the OEM model, there is little flexibility after the product design stage.

With contract manufacturing, on the other hand, a customer can get the manufacturer involved at any point – from conceptualization to assembly. The customer also works more closely with the manufacturer, ensuring more control over the process. Contract manufacturers are also willing to take consigned parts, work with customer-designated suppliers, and allow greater detail on part specifications.

Market Competitiveness and Brand Differentiation

Because OEM manufacturers typically cater to niche industries and product categories, it is highly likely that multiple businesses (which may include some of your direct competitors) will contract the same manufacturer. This can significantly diminish or eliminate brand differentiation, making your competitive edge mostly about branding and price.

| Consideration | OEM | Contract Manufacturing |

| Product Line | Highly specialized, existing products | Made to customer design, unique products |

| Initial investment costs | Low | Medium to High |

| Manufacturing flexibility | Low | High |

| Customer Level of Control | Low to Medium | High |

| Time-to-market speed | Medium | Low |

| Ownership of IP rights | Mixed IP Ownership | Customer owns IP fully |

| Market competitiveness and brand differentiation | Low to Medium | High |

| Company size and production volume | Large production volumes | Small and medium-sized businesses; with corresponding production volumes |

Table 2: OEM vs Contract Manufacturing: Factors to Consider

Examples of OEM and CM

Most businesses today outsource manufacturing, including major corporations.

For example, while Apple has the resources to build its own manufacturing facilities, it nevertheless relies on the OEM manufacturer Foxconn to produce its iconic iPhone. This model saves Apple billions in overhead facilities costs, workforce, and time, enabling the company to focus its resources on other aspects of the business.

Toyota is another example. The company contracts both OEM and CM manufacturers to produce and deliver the numerous parts that go into their vehicles. The company then assembles these components in-house to create the final product.

Conclusion

OEM and contract manufacturing are two of the most ubiquitous outsourced manufacturing models. Both have their advantages, and choosing the right one will depend on your business’s needs, goals, and resources.

Generally speaking, OEM is better suited to products in certain categories, like electronics and appliances, as well as large production runs. It’s also useful when time-to-market is critical or when design and production budgets are smaller.

Contract manufacturing, on the other hand, caters to numerous product categories across various industries. It is ideal for more custom products or companies that want complete ownership of the intellectual property rights.

FAQ

What’s the difference between OEM and contract manufacturing?

OEM is a production model that allows companies to use a manufacturer’s specialized infrastructure, pre-existing designs, and components to create a product line.

Contract manufacturing is more flexible and customizable, but requires the customer to invest more resources in designing the product, sourcing components, and purchasing the tooling required for production.

When should a company use OEM manufacturing?

OEM manufacturing is often a better option for companies that:

- Have a product in a category that is catered to by OEM manufacturers (e.g. electronics, appliances, automotive parts).

- Have a large production run.

- Want a faster time-to-market.

When should a company use contract manufacturing?

CM is typically better for companies that:

- Have a new or unique product, or a product in a category not serviced by many OEMs.

- Need to retain intellectual property rights over the entire design.

- Want more product differentiation to stand out from the competition.

What is turnkey manufacturing?

Turnkey manufacturing is an approach to contract manufacturing where a company relies on a single manufacturer to handle the entire production process – from design to delivery. In contrast, some companies opt to work with different manufacturers for parts of the production (e.g. one manufacturer for internal components and another for the external shell). Companies might also manufacture parts through CM but assemble the final product in their own facilities.